Categories

Wet Blast Cabinet with Closed Loop System is good for environment, and it does not require a running water supply to operate. You don't need to worry about waste water disposal. Some production shops might need a closed loop wet blast system because running water is not available or practical in the shop. If it is inconvenient to run a hose to the wet blast cabinet, or if running water is unavailable, a closed loop system is a good choice.

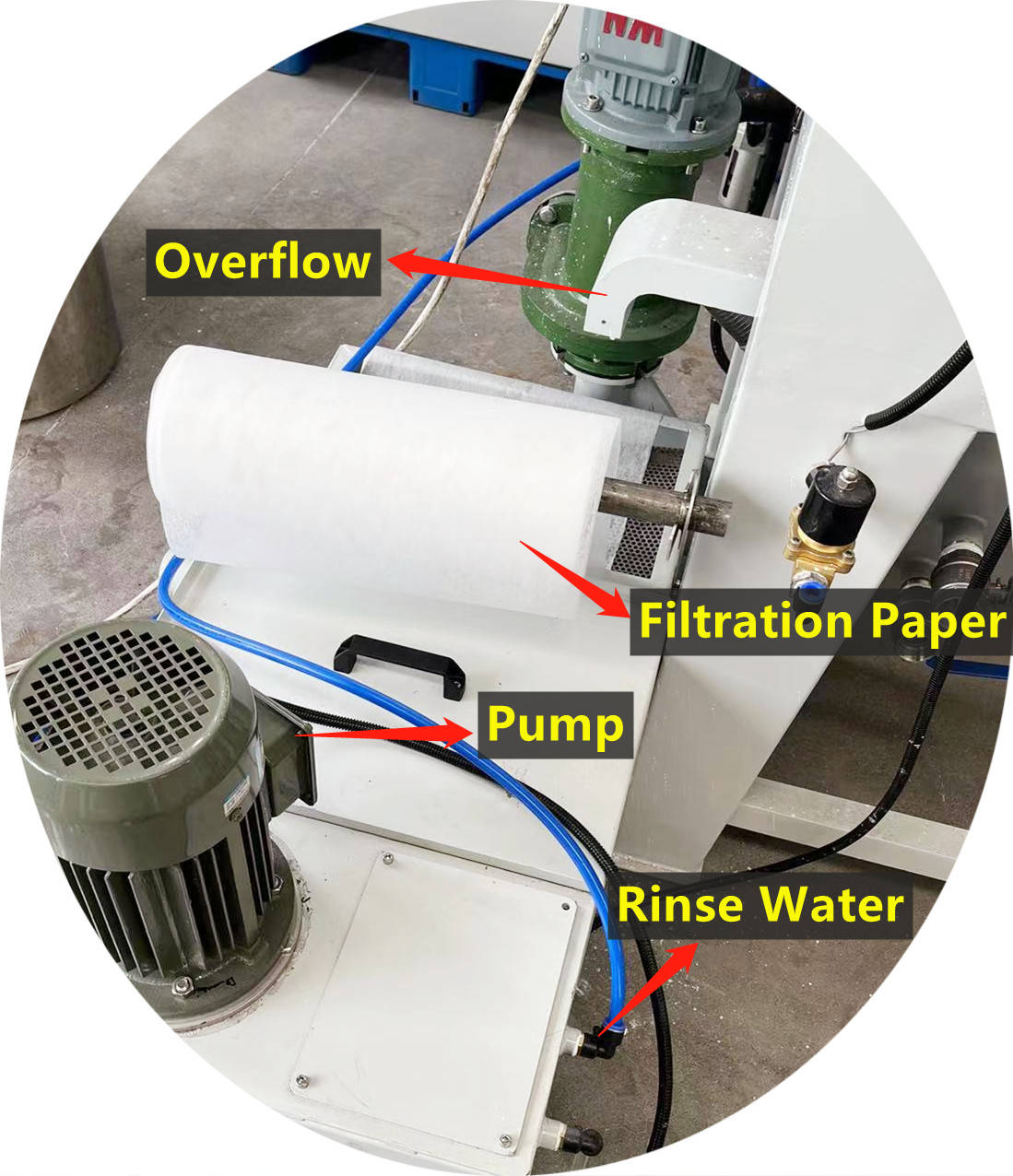

This overflow water passes over a metal tray with a paper filter, allowing particulates, dirt, grime, and spent abrasive to be filtered out from the circulated water. This leaves the water in the outside tank clean.

This overflow water passes over a metal tray with a paper filter, allowing particulates, dirt, grime, and spent abrasive to be filtered out from the circulated water. This leaves the water in the outside tank clean.

Spent abrasive and other particulates float to the top of the water, so these are easy to eliminate from the water supply with the filter in place. The unspent abrasive settles at the bottom of the hopper.

Whenever you use the rinse hose, water from the outside tank goes into the blast cabinet. The excess water goes from the overflow back into the external water tank, creating a closed loop.

The closed loop system reuses the water and slurry supply indefinitely, until you choose to drain the slurry mix from the cabinet.