Categories

Application

Wet blast cabinet

Wet blast cabinets are designed for wet blasting cleaning. There is a wide range from small manual cabinets suitable for automotive workshops to large automatic machines used for special applications, such as the surface preparation of wire and extruded products and also automatic cleaning of complex components and dies.

Wet blasting provides extremely consistent and reproducible surface treatment to clean, degrease, descale etc. or polish various products of various geometry and material (from plastic and soft metals to steel or exotic materials) without the use of harsh chemicals or dusty mechanical action.

Our wet blasting process is a solvent and dust-free blasting process and is safe also for the operator. Abrasive solution is a special mix of water and media, sometimes also a special detergent. This mix is projected at the work piece through an advanced blast nozzle.

Because no solvents or other potentially hazardous chemicals are used by the wet blast process, it is not subject to any solvent or dust emission legislation.

Advantages,

Greatly improving the dust pollution of the environment, and reduce the health hazards to workers.

No need to equip the ventilation and dust removal equipment and a separate blast room, can directly install in the production line, to save production areas, good to the turnover of the workpieces.

Flexible working methods, variable process parameters, can adopt to finish process requirements of different materials and different precision parts.

The surface quality improve after processing, at a reasonable selection of process parameters conditions, reduce the roughness one level after sand blasting.

The surface of workpieces will harder after sand blasting, to improve the wear resistance and fatigue strength.

In the working, the abrasives can recycling use, small consumption.

The main parts with long service life, and easy to maintain.

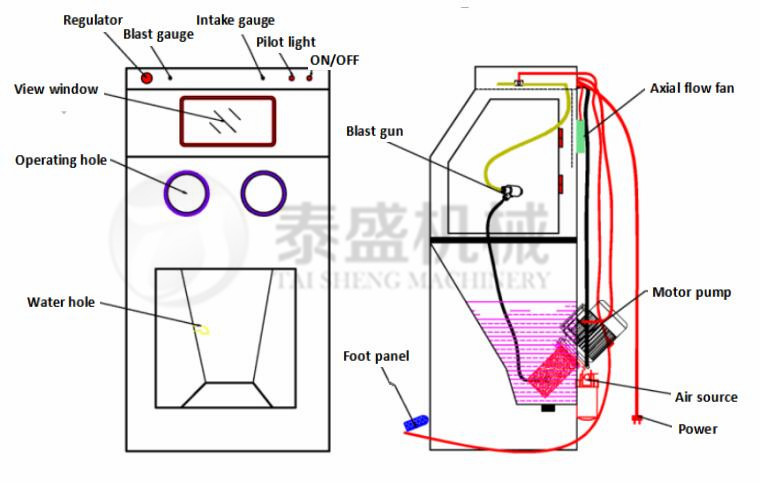

Machine Description

This is a small cleaning equipment, mainly composed by the cabinet, blasting system, sand pump, abrasive clean system, electrical system and etc. Water and abrasive mixing ratio 4-6:1(according to abrasive type), normally 3-5kg abrasive is enough.

Abrasive available: glass bead, aluminum oxide, sand and etc.

Standard Model

Wet Blast Cabinet (Power 380V±10%/50Hz/3Phase; 220V±10%/50Hz/Single Phase)

Model | Operating Zone(mm) | Total size(mm) | Compressed Air Supply | Power | Fabricate Material |

TS9065W | 900x650x600 | 1000x1000x1700 | 0.8-1.2m³/min; 3-7bar(kg/cm2) | 220V/380V 50HZ | Glass Fiber Reinforced Plastics |

TS9090W | 900x900x750 | 1000x1400x1830 | 0.8-1.2m³/min; 3-7bar(kg/cm2) | 220V/380V 50HZ | Glass Fiber Reinforced Plastics |

If you can't find suitable model, contact with us, we can design it for you.

Product Pictures

Welcome to watch our videos,