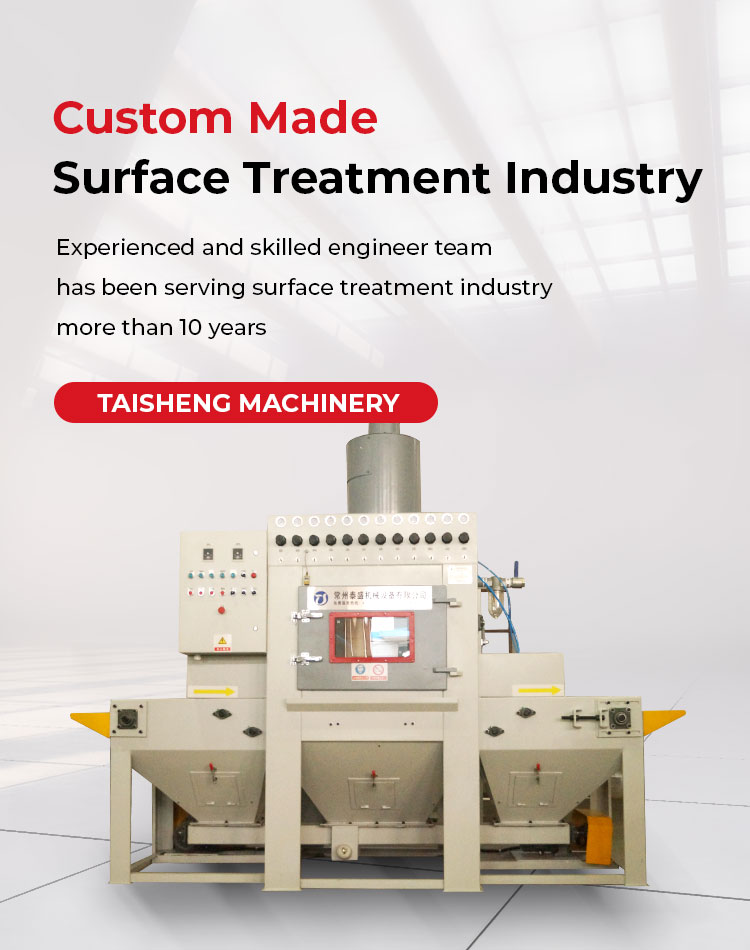

Changzhou Taisheng Machinery Co., Ltd.

Changzhou Taisheng Machinery Co., Ltd. has been engaged in producing sand blasting equipment, sand blasting room and shot blasting machine since 2007. Specializes in designing standard and custom made products, provides a complete set of surface finishing solution to customer.

If You Have Special Requirements

Contact Us Now

Contact Us Now

Do you want to buy sandblasting and shot blasting equipment? Do you want to see the latest design?

Top Categories

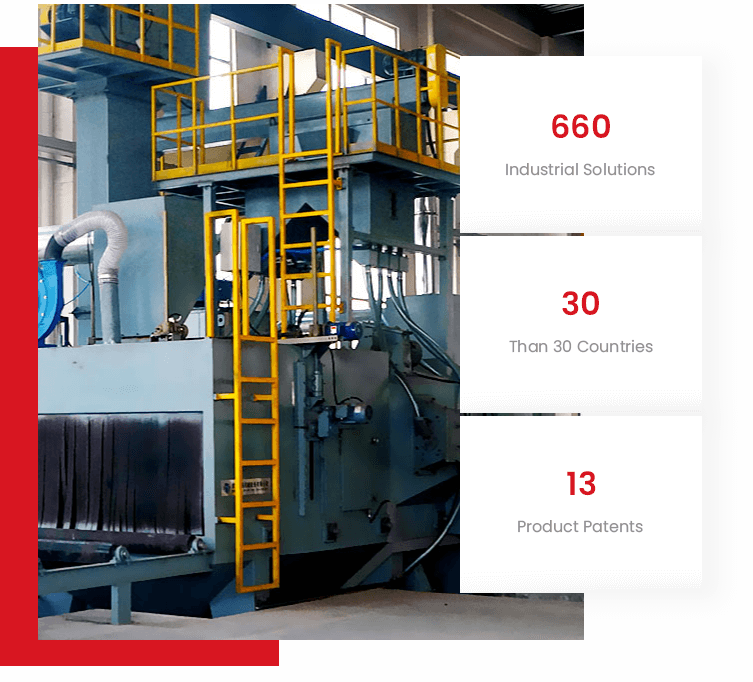

The company's products are widely used in petroleum, chemical, shipbuilding, automobile manufacturing, containers, construction machinery, military industry, wind power, electric power, port machinery, aerospace, electronic and electrical, energy, environmental protection, papermaking, semiconductors.

Industry Application

Equipment supplier of fortune 500 companies, our quality is rel.

Why Choose Us

Production Process

Professional quality, integrity to create success

Engineering and Design

Engineering and Design

Laser Cutting

Laser Cutting

Welding

Welding

Painting

Painting

Assemble

Assemble

Testing

Testing

Package

Package

Latest News

In the ever-evolving world of industrial surface preparation, portable shot blasting machines have become indispensable. These compact yet powerful units are designed to tackle a wide range of surface finishing tasks with precision and efficiency.

Read MoreWhen it comes to reliable and high-quality tumble belt machines, Taisheng Machinery is a name you can trust. As a leading supplier in the industry, Taisheng Machinery specializes in providing top-of-the-line tumble belt machines that streamline the surface finishing process.

A Turntable Blast Cabinet is a specialized piece of equipment used for surface preparation and finishing. The Turntable Blast Cabinet is designed to clean, deburr, and prepare the surfaces of various workpieces through a process called abrasive blasting.

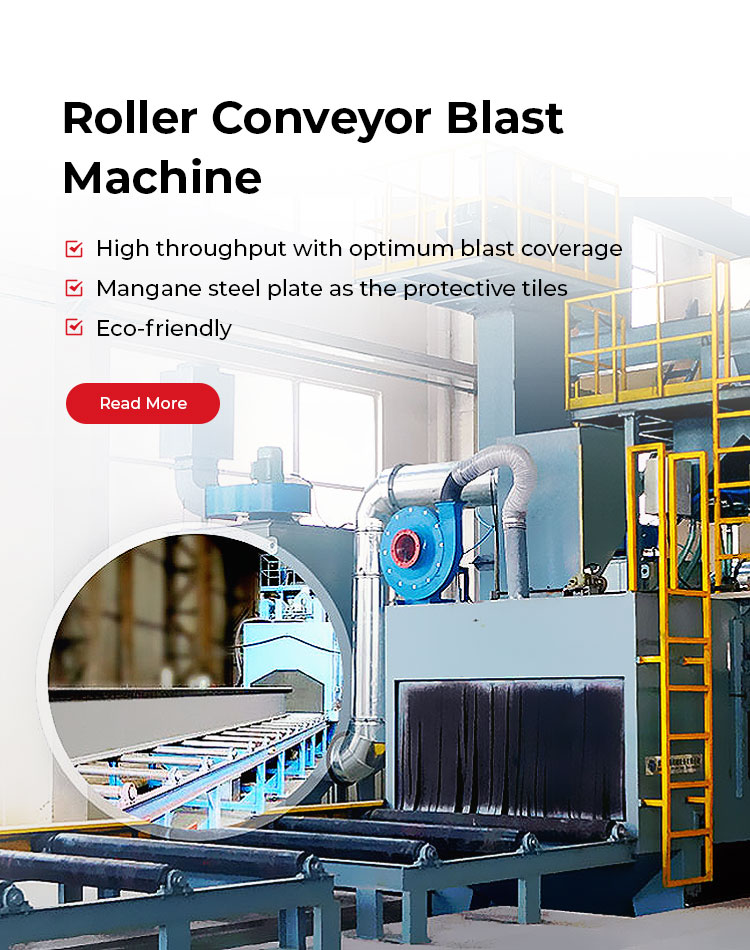

A roller conveyor blast machine is a type of industrial equipment used for cleaning, descaling, or surface preparation of workpieces in various industries such as manufacturing, automotive, foundry, and metal fabrication. It is specifically designed to handle large and heavy workpieces that can be transported on a roller conveyor system.

Roller conveyor blast machines are integral to the surface preparation industry, offering efficient and effective cleaning, descaling, and deburring solutions for a wide range of materials. These machines utilize a continuous and automated blasting process, making them indispensable for industries such as automotive, aerospace, foundries, and metal fabrication.

Surface preparation is a critical step in various industries, including manufacturing, automotive, and construction. Quality roller conveyor blast machines have emerged as indispensable tools in achieving efficient and effective surface cleaning, preparation, and finishing.