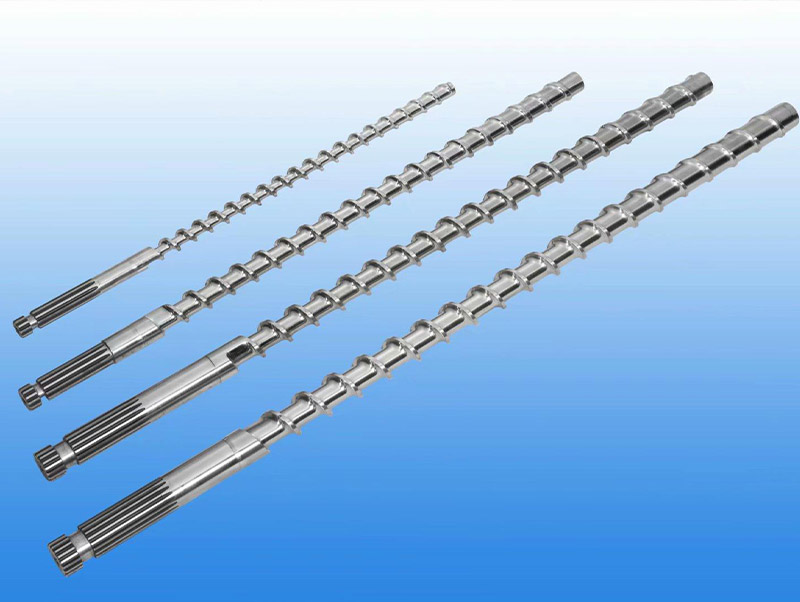

Screw Sand Blasting Cabinet

10/08/2021

10/08/2021Plastic Extrusion Screw Automatic Cleaning Machine

1. Applications

Widely used in treating all kinds of extrusion screw surface, does not hurt the screw.

2. Features

The machine is equipped with adjustable cyclone separator, it can sort the good abrasive out from the mixture for recycling use, greatly reduce the abrasive consumption.

Dust will be sucked into our bag dust collector keeping the cabinet ventilated and visually clear for the operator.

Heavy duty wear resistant rubber gloves to protect the operator and provide long service life.

Quick replace laminated glass viewing window requires no tools to change.

Compressed air regulator and gauge to allow the blasting pressure to be varied for different applications.

High performance pressure blast gun to provide faster and more effective cleaning.

Available abrasive size: 36-320mesh.

3. Working Principle

It’s a pressure type sand blast machine, consists of blasting cabinet, abrasive circulation system and dust collector. Using the compressed air as the power, produce the working pressure to suct the abrasive into blasting gun to hit onto the surface of work piece. It equips with high working pressure and peening volume.

Abrasive Circulation System: the used abrasives are carried by screw into elevator, and then transported to separator, the good abrasive are recycled into hopper for next blasting, the waste and dust are extracted into dust collector.

4. Basic Technical Specification

No. | Model | TS3210-3P | ||

1 | Maximum Screw Diameter | <3000mm | ||

2 | Recommend Abrasive | Walnut Shell | ||

3 | External Dimension | L3200mm * W1000mm * H2250mm | ||

4 | Blast System | Qty of Gun | 3pcs | |

Blast Nozzle Material | Boron Carbide | |||

5 | Load Capacity | <60kg | ||

6 | Workpiece Locking and Rotate Method | Qty | 1set | |

Rotate System | automatic | |||

Power | 0.4kw(with variable speed) | |||

7 | Workpiece Supportive Basement | Qty | 1set | |

Moveable | according to workpiece length; with locking system | |||

Mechanism | Two driven roller(covered by polyurethane) | |||

8 | Gun Running System | Qty | 1set | |

Move System | Forward and backward(driven by reducer) | |||

Power | 400w(with variable speed) | |||

9 | Sand Blast Tank | Diameter | 600mm | |

Volume | 0.3m³ | |||

Abrasive Feeding Method | automatic | |||

10 | Abrasive Circulation System | Bottom Screw | Capacity | 15ton/h |

Power | 0.75kw | |||

Elevator | Capacity | 15ton/h | ||

Power | 1.5kw | |||

11 | Dust Collector | Dust Cleaning Method | Automatic Pulse Jet Cleaning System | |

Capacity | 6677~13353m3/h | |||

Qty of Cartridge | 4pcs; Φ350mm x H1000mm | |||

Fan Power | 4kw | |||

12 | Machine Internal Light | 0.025kw x 4pcs | ||

13 | Total Power | Elevator 1.5kw |

| |

Screw Conveyor 0.75kw | about 7.2kw | |||

Rotate System 0.4kw | ||||

Running System 0.4kw | ||||

Fan 4kw | ||||

Light 0.025kw x 4pcs | ||||

14 | Compressed Air Supply | Working Pressure | 0.6-0.7Mapa; | |

Air Consumption | 5-6m3/min/gun | |||

15 | Power Supply | 380V ±10% 50Hz | ||

16 | Noise Level | ≤85dBA | ||

17 | Dust emission | ≤80mg/m3 | ||

Note: our equipment can be designed according to customer special requirements