Categories

Machine Description

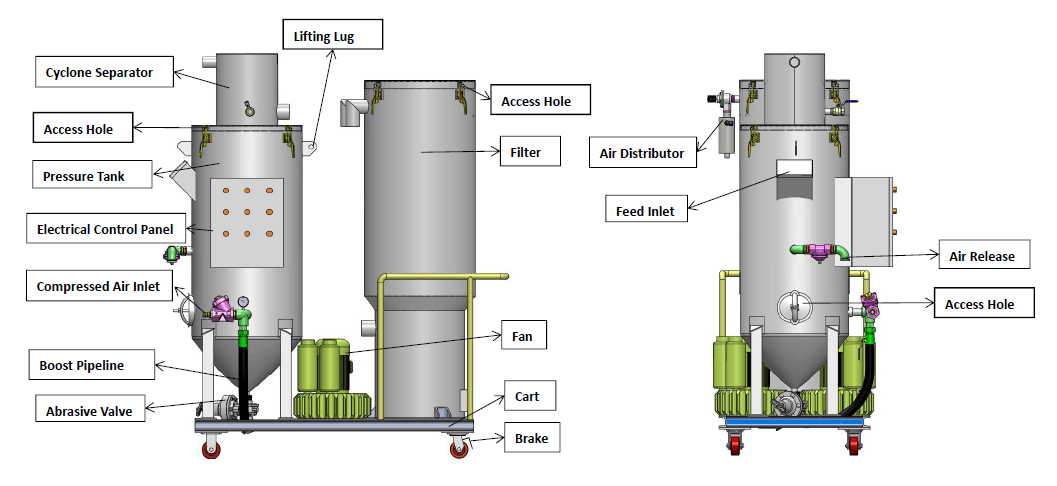

Vacuum Blasting Machine

Vacuum, or dust free blasting is ideal for spot repairs, and has high demand on the environment which should be dust free and abrasive pollution is prohibited.

The blasting process is happened in a sealed chamber by the brush head, curve or flat. Dust and abrasives are immediately vacuumed by a powerful suction fan. The used abrasives are recycled to the separator and silo, the dust is collector by the cartridge filter. TS machinery vacuum blasting is a safe blasting solution for confined or critical areas (with a lower working speed compared to “open” blasting).

Vacuum sand blast machine consists of Blasting System, Abrasive Recycle System(high centrifugal fan, recycle sand pipe, separator, hopper), Dust Removal System and Electric Control System etc.

Technical Parameter

Model | TS-150L | TS-300L |

Overall Size | 2200×1000×2000mm(L*W*H) | 2200mm x 1000mm x 2300mm(L*W*H) |

Weight | About 400kg | About 450kg |

Voltage | 380V 50HZ | 380V 50HZ |

The dia of nozzle | 6mm | 6mm;9mm |

Working pressure | 4-7bar | 4-7bar |

Working radius | 10m; 20m; 40m; 60m | 10m; 20m; 40m; 60m |

Working efficiency | 4-6m²/h(determined by operator proficiency, abrasive type, working radius, surface requirement and etc) | 8-12m²/h(determined by operator proficiency, abrasive type, working radius, surface requirement and etc) |

Working type | Automatic recycle type | Automatic recycle type |

Compressed Air Consumption | 2-3m³/min | 5-6m³/min |

Fan power | 5kw; 8kw(as per the working radius) | 7.5kw; 8kw; 11kw(as per the working radius) |

Filtration area | About 20m² | About 20m² |

Cleaning level | Sa2.5-3 | Sa2.5-3 |

Roughness | 40-70μm | 40-70μm |

Usable abrasive | G50 bearing steel grits | G50 bearing steel grits |

Application

Benefits if using TS vacuum blasting,

● 100% dust free operation because of fully automated vacuum start/stop sequence

● Clean, abrasive free surface after blasting

● Automatic filter cleaning system

● Easy disposal of collected dust in a plastic bag

● Unit can be movable easily

● Wide range of brushes to fit all (flat, cornered, radius) surfaces

You can use it by hand,

or mounted on blasting gun rack like this

Brushes (flat, cornered, radius)

Welcome to watch our video,